Remediation work by injection

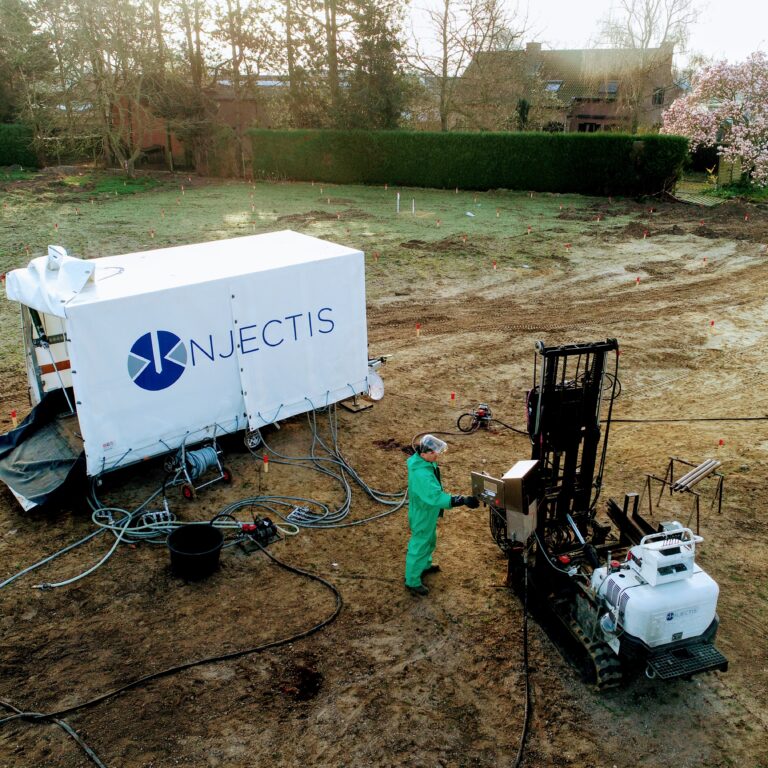

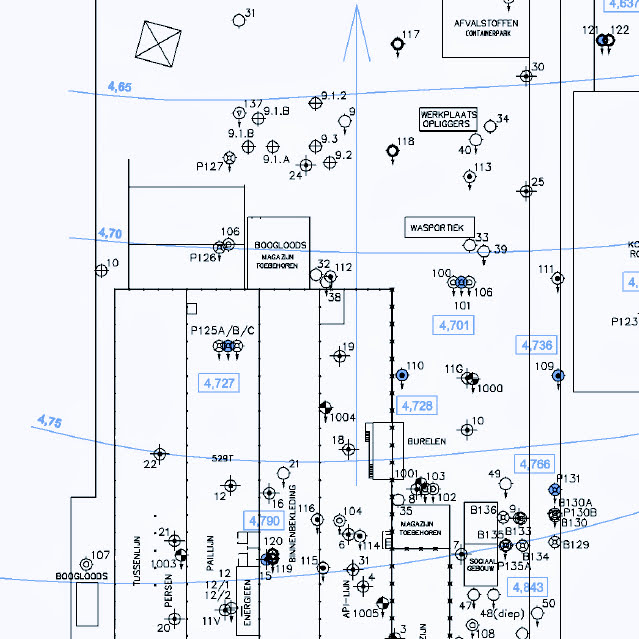

- Setting up and positioning of injection points > Site visits, on-site measurements for the positioning of injection points, taking into account the ground conditions.

- Injections > Carrying out injections with our various machines equipped with our patented SPIN® technology. Carried out by our specialized and experienced technicians supervised by our engineers.

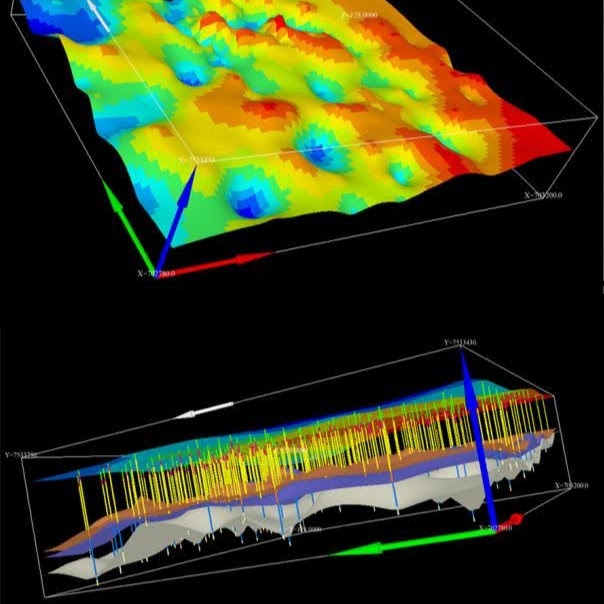

- Parameter monitoring > Real-time measurement of the evolution of the necessary parameters, as well as post-treatment monitoring of the effectiveness of the treatment (advice or support with post-treatment drilling and groundwater sampling campaigns).

- Results > Processing injection campaigns results and measuring treatment effectiveness with regard to the established remedial goals.

Laboratory testing

- Each project has its own tests for optimal results > Each project is accurately studied to ensure that injections achieve their full treatment potential. In its own laboratory, Injectis carries out the appropriate tests in order to simulate the best conditions for biological or chemical degradation, thus being able to adapt along the way to the observations for optimal results.

- Saving time and money > By limiting intermediaries, Injectis can adapt delivery times for each project but can also reduce costs by carrying out the appropriate tests consistent with our business.

- The right reagents for the right project > The right reagents for the right project. The various products on the market can be tested to determine the choice of product or to produce the most effective mixture and thus develop the appropriate formula taking into account the environmental conditions and the actual state of the ground.

- Protocols adapted to ground conditions > There are of course other laboratories, but as they are often external to the field of in situ decontamination, they implement a protocol to be followed without always taking into account the actual state of the ground. Injectis knows perfectly well the purpose of the tests and seeks the result so that the injection conditions are feasible and deploys the full potential of the remediation treatment.

Advice

- Expertise of the project in its entirety > As remediation company with extensive experience in engineering offices, Injectis engineers can understand projects in their entirety and provide technical expert opinion or specific advice.

- Second opinion or counter-expertise > Given what is at stake, a second opinion is often desirable. Without any obligation, Injectis studies your file from a new angle. More frequently, Injectis receives files after the clean-up work has been completed because the results have not meet the expected goals. Do not wait until it is too late.

- A simple call can quickly solve your doubts > In a world where minutes are charged, Injectis wants to continue to make advice available and accessible in order to collaborate towards a common goal: finding the best solution. Send us your questions, we will be happy to help you with our theoretical and on the field experience!

- Alternative proposal (BATNEEC principle) > Engineering offices must compare the different techniques available in order to choose the best technique at the best cost. Injectis offers you a brief feasibility analysis based on a few key elements of your file at any state of progress.

Pilot test

- Small-scale scalable test (3-7 injections) > The pilot test carried out under real conditions allows us to see how the environment reacts. Although not essential, it is part of a reasonable decision-making process and will help to determine the size of the full-scale treatment and define:

- the most effective products/reagents,

- the appropriate concentrations,

- the radius of influence for the areas to be treated,

- the practically achievable and feasible goals for the project,

- and all the physical-chemical parameters of the environment that would be missing at this stage of the study.

- Economic: a small investment for big savings > The results of the pilot test will allow the adjustment of the injection distances and validate the reagent(s) and the concentrations, in order to define the right parameters and optimize the efficiency of the soil remediation. Savings of 20 to sometimes 50% can be made on a full-scale soil remediation.

- Fast: around 1 to 2 weeks > Depending on the number of injections chosen and the depth of the pollution, the pilot test can be carried out quickly, and generally it does not require the interruption of an ongoing activity for more than a week.

- Part of the treatment carried out > Depending on the extent of the pollution, the pilot test sometimes treats a significant part of the pollution. This expense is no longer necessary and is directly profitable.